The Hidden Costs of Poor Product Information Management

- The big picture: Poor information management leads to operational inefficiencies, negative customer experiences, and legal and compliance risks for businesses.

- Why it matters: Poor product information can increase operational costs, create missed opportunities for sales, and result in regulatory fines, significantly impacting a company's bottom line.

- The bottom line: Improving product information management enhances operational efficiency, boosts employee satisfaction, and provides decision makers with actionable insights for informed decisions.

In this Article

ABC Inc. is a mid-sized industrial-grade equipment manufacturer whose sales have declined for the past two years. Despite producing top-tier products, they’re steadily losing market share to competitors. Management has tried everything from aggressive marketing campaigns to price adjustments, but nothing seems to work.

During a tense brainstorming session, Tim, a junior product manager, notices something alarming: inconsistencies in product descriptions, outdated records, and a general lack of clarity across various sales channels. His hypothesis: the company’s poor records management practices are not just a minor oversight but a ticking time bomb, silently undermining their sales efforts and eliminating their competitive advantage.

However, the CEO dismisses the idea, believing that poor information management couldn’t possibly be the root cause of their significant sales slump. As the meeting adjourns, Tim can’t shake the feeling that something seemingly simple might be the critical issue. Could these subtle discrepancies really be costing them so much? And if so, how?

Understanding Poor Product Information Management

What amounts to poor product information management?

First, what is Product information management (PIM)? PIM encompasses the business processes and technology that organizations use to collect, manage, enrich, and distribute all the information needed to market and sell products. The information typically includes technical specifications, product descriptions, pricing, and other relevant details stored as structured data.

Effective PIM has several objectives, which when achieved can deliver value and drive revenue for your business:

Data consistency: Ensure consistent and accurate product information across all channels and touchpoints, providing reliable information to customers.

Operational efficiency: Streamline business processes for creating, updating, and distributing product information to reduce errors and boost productivity.

Time-to-market optimization: Enable faster product launches and updates by having readily available, accurate information through proper knowledge management.

Enhanced customer experience: Provide comprehensive, accurate, and up-to-date product information to support informed decisions and improve customer behavior.

Improved decision-making: Facilitate better business insights through reliable and easily accessible structured data that provides actionable insights.

Compliance and regulatory adherence: Ensure product information meets regulatory requirements and standards, avoiding legal and compliance risks while protecting intellectual property.

So it stands to reason that poor records management occurs without effective PIM. In other words, bad information management is the mishandling, disorganization, or inconsistent distribution of product-related data across an organization and its various sales channels—often resulting from inadequate information storage systems and poor records management practices.

How does poor product information manifest?

We met Tim (the junior product manager at ABC Inc.) earlier and learned that he noticed inconsistencies in product descriptions, outdated records, and a general lack of clarity across various sales channels. These observations summarize the symptoms of poor information management.

Other symptoms include:

Inconsistent product information across different platforms

Incomplete or missing product details in documents and records

Difficulty in updating product information across all channels simultaneously

Inability to quickly adapt to market changes or launch new products efficiently

Lack of access controls over sensitive information

Wasted time searching for reliable information across massive amounts of data

When these symptoms reveal themselves, the organization can quickly descend into the danger zone. This is because poor records management has far-reaching impacts. Let’s see an illustration.

An illustration of the impact of poor information management

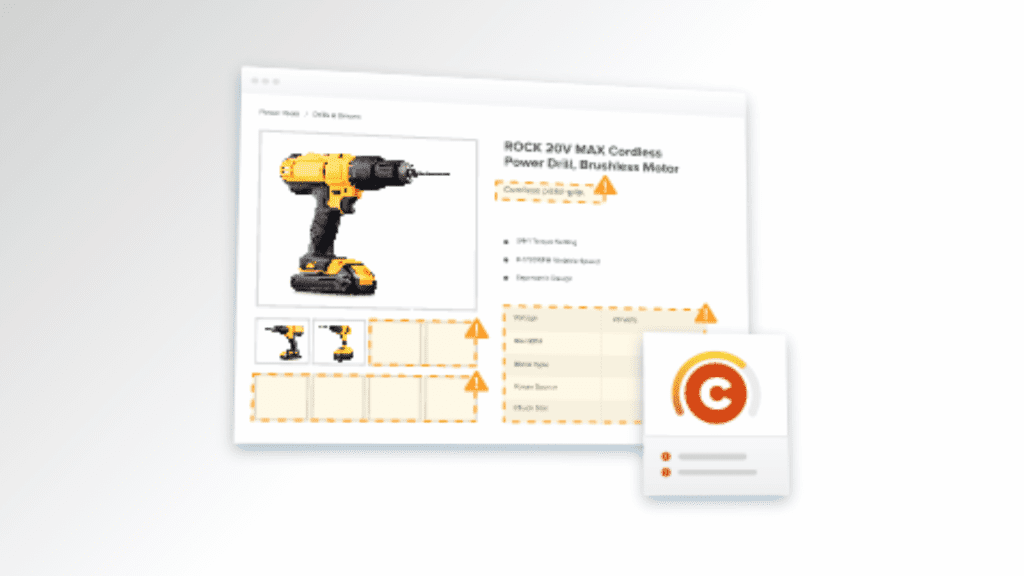

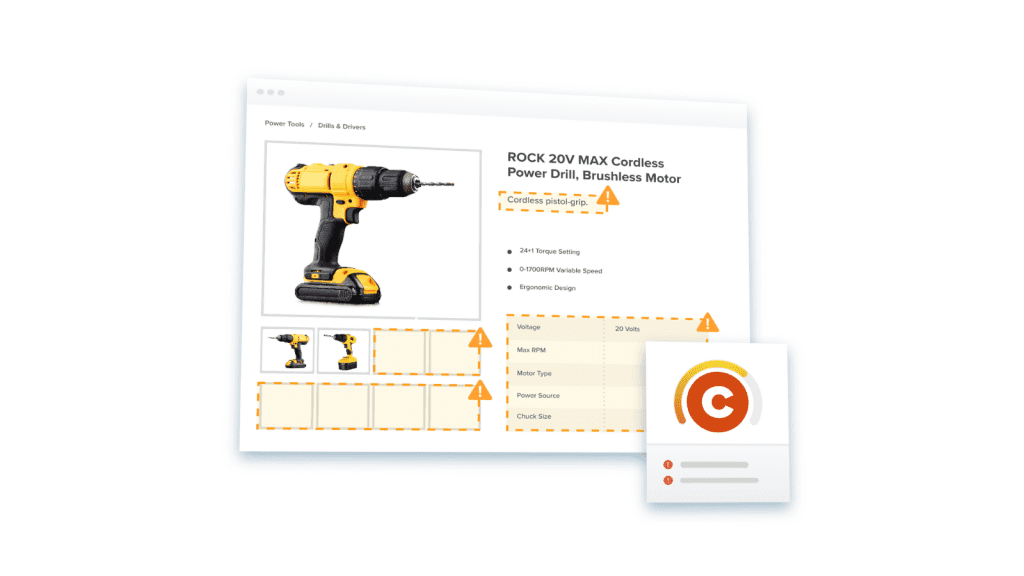

Let’s return to ABC Inc. for this illustration. Suppose that one of their flagship products is a heavy-duty industrial drill press. The company website describes the drill press as having a maximum drilling capacity of 1.5 inches. However, in the product catalog distributed to distributors, the same drill press is listed as having a capacity of 2 inches.

This discrepancy creates a cascade of problems. Firstly, customers who rely on the website information may purchase the drill press expecting it to handle their specific drilling needs, only to find it underpowered. With much frustration in their hearts, the disappointed buyers will return the product and leave negative reviews.

Secondly, distributors might oversell the product’s capabilities, attracting the anger of dissatisfied customers.

Thirdly, internal teams like customer support and sales face challenges due to poor information. When customers ask questions about the drill press’s capacity, support agents must consult multiple sources and risk providing incorrect information. Sales representatives may also struggle to provide accurate quotes to customers, hindering the sales process.

This simple example provides a vital snippet of the hidden costs of poor product information management. The following section reveals these costs and discusses them in detail.

How does poor product information management manifest?

We met Tim (the junior product manager at ABC Inc.) earlier and learned that he noticed inconsistencies in product descriptions, outdated specifications, and a general lack of clarity across various sales channels. These observations summarize the symptoms of poor product information management.

Other symptoms include:

- Inconsistent product information across different platforms

- Incomplete or missing product details

- Difficulty in updating product information across all channels simultaneously

- Inability to quickly adapt to market changes or launch new products efficiently

When these symptoms reveal themselves, the organization is often too deep into the danger zone. This is because poor product information management has far-reaching impacts. Let’s see an illustration.

An illustration of the impact of poor product information management

Let’s return to ABC Inc. for this illustration. Suppose that one of their flagship products is a heavy-duty industrial drill press. The company website describes the drill press as having a maximum drilling capacity of 1.5 inches. However, in the product catalog distributed to distributors, the same drill press is listed as having a capacity of 2 inches.

This discrepancy creates a cascade of problems. Firstly, customers who rely on the website information may purchase the drill press expecting it to handle their specific drilling needs, only to find it underpowered. With much frustration in their hearts, the disappointed buyers will return the product and leave negative reviews.

Secondly, distributors might oversell the product’s capabilities, attracting the anger of dissatisfied customers.

Thirdly, internal teams like customer support and sales face challenges due to inconsistent information. When customers ask questions about the drill press’s capacity, support agents must consult multiple sources and risk providing incorrect information. Sales representatives may also struggle to provide accurate quotes to customers, hindering the sales process.

This simple example provides a vital snippet of the hidden costs of poor product information management. The following section reveals these costs and discusses them in detail.

The Hidden Costs of Mis-Managed Product Data

The immediate consequences of poor information management often seem minor. In fact, it may take considerable time before management realizes that the business is not achieving sales objectives because of poor records management practices. These costs start small and snowball into significant issues whose impact reveals itself in poor sales and slow decision making.

The problem is that the hidden costs permeate various aspects of business operations, from day-to-day processes to long-term strategic goals, making it difficult for decision makers to regain control.

1. Operational inefficiencies

One of the most immediate consequences of bad information management is increased operational inefficiencies and reduced productivity. Manual interventions become the norm as employees scramble to correct errors, update information, and resolve customer inquiries arising from inaccurate product details. This constant firefighting consumes valuable time and resources, leading to wasted time across the organization.

The constant firefighting inevitably increases the costs of running the business. Every manual correction, every customer return, and every delayed shipment due to incorrect information adds to the operational burden. Some of the costs you’ll see go up include overtime pay for employees, restocking fees, and shipping expenses. Moreover, the time spent resolving issues related to poor product information diverts resources away from strategic initiatives, hindering overall business growth and creating missed opportunities.

Beyond financial implications, poor records management can increase the time between ideation and launching a new product to the market. Accurate and comprehensive product information is essential for marketing, sales, and distribution channels to function smoothly. When product data is inconsistent or incomplete, it creates bottlenecks in the product launch process.

For instance, marketing materials cannot be produced on time, sales teams are ill-equipped to engage with customers, and distribution channels face delays in stocking and shipping products. The cumulative effect is longer time-to-market, resulting in potential revenue loss and a weakened market position that erodes competitive advantage.

2. Negative customer experience

Poor information directly translates to a subpar customer experience. When customers encounter inaccurate or inconsistent information, frustration and confusion inevitably follow. Simple questions about product features, compatibility, or dimensions can become insurmountable obstacles when the provided information is unreliable. This leads to a growing sense of dissatisfaction and negative customer behavior.

A direct consequence of these frustrations is increased negative reviews and returns. Customers who receive products that don’t match their expectations are more likely to express their disappointment publicly through online reviews. Negative reviews, mainly when not adequately addressed, damage your brand’s credibility, which deters potential customers and reduces the overall value proposition.

Increased return rates are another costly byproduct of poor records management. When product details are misleading, customers often end up with items that don’t meet their needs. Returning a product is inconvenient and time-consuming for customers and incurs significant business expenses. Shipping costs, restocking fees, and potential product damage all contribute to the financial impact of returns. Moreover, high return rates can strain inventory management, leading to stockouts or overstocking, further exacerbating operational challenges.

Beyond the immediate financial costs, a high return rate can also have a long-term impact on customer loyalty. Customers with an unpleasant return experience are less likely to make future purchases, leading to a decline in repeat business and reduced costs from customer lifetime value.

3. Regulatory and compliance risks

Poor information management can lead businesses into trouble with authorities and established norms. One of the primary legal and compliance risks is the possibility of legal penalties and compliance violations. Many industries are subject to strict regulatory requirements regarding product labeling, safety information, and disclosure of specific product characteristics.

For instance, in the industrial equipment sector, failing to list products’ safety specifications or operational limits accurately can result in regulatory fines. On the other hand, manufacturers may attract legal action from regulatory bodies when they share incomplete or inaccurate information about machine capabilities or safety features. This lack of control over sensitive information can also lead to data breaches if proper access controls aren’t in place. Even in less regulated industries, misrepresenting product features or capabilities can set a company up for lawsuits from consumers or regulatory agencies, potentially exposing intellectual property to legal discovery.

These legal penalties can be substantial, often involving hefty regulatory fines directly impacting a company’s financial health. Beyond the immediate financial cost, legal issues can also lead to increased regulatory scrutiny, potentially complicating future operations and product launches.

Perhaps even more damaging than legal penalties are product recalls necessitated by inaccurate or incomplete product information. When crucial product details are mismanaged through poor records management practices, it can lead to situations where products in the market don’t meet safety standards or perform as advertised. In such cases, companies may have to issue a recall and potentially destroy records to prevent further distribution.

The financial impact of a product recall can be enormous. It involves not just the cost of retrieving and replacing the product but also potential compensation to affected customers, legal fees, and the expense of corrective advertising campaigns.

Beyond the financial aspect, product recalls can severely damage a company’s reputation. In the age of social media and instant messaging, news of a recall spreads quickly, potentially tarnishing a brand’s image for years to come. This reputational damage can take away huge chunks or a total loss of market share and possibly make it impossible to launch new products, eliminating any competitive advantage the company once held.

4. Analytical challenges

Most businesses rely on business intelligence (BI) to make decisions. This is crucial because, to these organizations, even the most mundane decision could generate repercussions reverberating across the entire business. Organizations can make excellent informed decisions only when depending on accurate insights and reliable information.

However, poor information management creates significant analytical challenges, resulting in misguided decisions and slow decision making. When data is inaccurate or incomplete, it skews the analysis, leading to faulty conclusions and strategic missteps. Decision makers struggle to extract actionable insights from poor information, creating missed opportunities across the business.

For example, consider a scenario where ABC Inc.’s (the power tools manufacturer we met earlier in the introduction) product information database inaccurately reports the sales figures of their industrial drill presses due to incorrect product categorization. As a result, the company’s management might mistakenly believe that a particular model is underperforming and decide to discontinue it. However, the issue could be related to mislabeling or poor categorization rather than product quality or market demand. This misinterpretation could lead to the unnecessary discontinuation of a profitable product line, resulting in lost revenue and market share.

Another instance of misguided decision-making could occur in inventory management. Suppose inaccurate product specifications lead to overestimations of demand for specific components. In that case, the company might overstock those items, tying up capital in excess inventory that doesn’t move as expected.

The hidden costs of these poor decisions can be substantial. They include not only the direct financial losses from wrong strategic moves but also the opportunity costs of not pursuing more profitable avenues—true missed opportunities to drive revenue. Additionally, incorrect data can lead to inefficient resource allocation, further exacerbating operational inefficiencies and hindering the ability to store information effectively for future knowledge management.

These challenges highlight the critical need for effective product information management to support effective decision-making and strategic planning. Without proper knowledge management and reliable information, companies risk making decisions based on faulty premises, ultimately undermining their competitiveness and profitability.

The Solution: How to Regain Control

So what can Tim do now? How can he convince management that poor records management practices are indeed the culprit and, more importantly, that there’s a solution?

First, Tim might want to present the issues we’ve discussed. He could ask, “Have we noticed increased customer complaints about product inconsistencies? Are our teams experiencing wasted time correcting errors? Are we losing our competitive advantage to rivals with better information systems?” These questions can help management see the connection between their current challenges and poor information management.

But Tim shouldn’t stop at identifying the problem. He needs to offer solutions. For instance, he can suggest that implementing proper technology and business processes through a RIM program (Records and Information Management program) or PIM software can prevent most, if not all, of these challenges.

“What if we had a robust product information management solution that could aggregate, manage, enrich, and distribute our product details?” Tim could propose. “A solution that ensures every department, from marketing to sales to customer service, has access controls to the same, up-to-date structured data?”

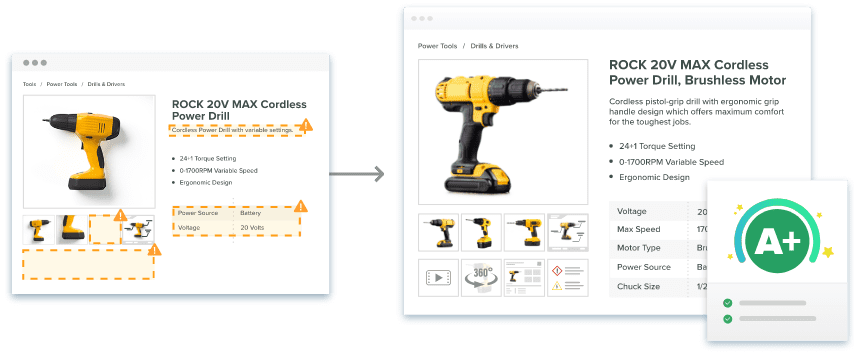

This is precisely what a PIM software solution offers. It’s not just about having a database to store information; it’s about having a robust system with proper accessibility and control that can:

Streamline data entry and updates across the information lifecycle

Ensure consistency across all channels with reliable information

Automate many of the manual processes that are currently eating up time and introducing errors

Provide decision makers with actionable insights for informed decisions

Implement proper access controls to protect sensitive information and intellectual property

Of course, implementing a PIM solution is just one part of the solution. Tim could also suggest some best practices to complement the technology, including:

Regular audits to keep information up-to-date and accurate throughout the information lifecycle

Clear guidelines for data entry and management to improve knowledge management

Training programs to ensure everyone understands the importance of good product information and boost employee satisfaction

Proper protocols to securely shredded outdated records when necessary

Implementing access controls to protect sensitive information from data breaches

“But isn’t this going to be expensive and time-consuming to implement?” management might ask. Tim can counter this by highlighting the potential benefits and long-term value: reduced costs from improved operational efficiency, improved customer satisfaction that can drive revenue, fewer returns, and better-informed business decisions based on actionable insights. While there’s an initial investment required, the reduced costs and missed opportunities recovered will quickly justify the expense.

In the end, Tim can emphasize that investing in better product information management isn’t just about solving current problems—it’s about setting up the company for future success. By addressing poor records management practices now, ABC Inc. can regain control of their data, restore their competitive advantage, and transform massive amounts of documents and records into structured data that drives business value.

Presenting this comprehensive approach allows Tim to show that he’s not just identified a problem but also found a practical, effective solution. And who knows? This could be the turning point that puts ABC Inc. back on the growth path, with proper technology and business processes in place to support sustainable growth and productivity gains across the entire organization.

PIM refers to the processes and tools that aggregate, manage, and distribute product details across various channels. For manufacturers, PIM is crucial because it ensures consistency and accuracy of product information, which is vital for maintaining brand integrity and meeting customer expectations. Effective PIM enables efficient management of complex product catalogs, supports compliance with industry regulations, and facilitates quicker time-to-market for new products.

When product data is inconsistent, outdated, or inaccurate, customers may receive incorrect information about a product’s features, specifications, or availability. This creates dissatisfaction, as customers might feel misled or disappointed. The result is often negative reviews, increased returns, and loss of customer trust. Additionally, repeated issues with product information can damage a company’s reputation, as customers may perceive the business as unreliable or unprofessional. In the long term, these negative perceptions can reduce customer loyalty and deter potential new customers.

Several factors contribute to poor product information management, including:

- Manual data entry: Reliance on human intervention to create product information increases the likelihood of errors and inconsistencies.

- Lack of standardization: Inconsistent data formats and terminologies across departments create scenarios for inaccuracies to crop up.

- Information segregation: When product information is scattered across multiple systems or departments, it becomes challenging to ensure consistency and accuracy.

- Outdated product information management solutions: Antiquated or inadequate solutions, such as spreadsheets, for managing product data, create the perfect environment for poor product information management practices.

- Insufficient training: Employees may not be adequately trained on best data entry and management practices, leading to mistakes and inefficiencies.

Improving product information management requires a multi-faceted approach:

- Implementing a PIM solution: A robust PIM solution collects product information from different sources and creates a centralized and secure repository. The solution integrates with several platforms, including e-commerce platforms like Shopify, distributors, and retailers, to facilitate seamless product information syndication. This ensures consistency and accuracy across all channels.

- Establishing data governance policies: Clear policies and guidelines for data entry, management, and updates help maintain data quality and integrity.

- Regular audits: Periodic audits of product information help identify and correct discrepancies, ensuring data remains accurate and up-to-date.

- Employee training: Training programs educate employees on the importance of accurate data management and best practices for maintaining data quality.

Failing to manage product information effectively can have several financial implications for a company. These include increased operational costs due to manual interventions, corrections, and handling customer complaints. Poor product information can lead to high return rates, resulting in additional expenses for restocking, shipping, and processing refunds. Moreover, inaccuracies in product data can delay time-to-market for new products, causing lost revenue opportunities. Compliance issues from incorrect product information can result in legal penalties and fines. Lastly, a tarnished reputation due to customer dissatisfaction can decrease sales and market share, affecting overall profitability. Therefore, proper product information management practices are essential for maintaining a healthy bottom line.