Driving Sales with Product Data: How PIM Empowers Brands

Listen to a summary of this article, powered by NotebookLM:

- Product data is an invaluable sales driver for industrial brands.

- Managing complex product data is challenging without proper solutions.

- A unified PIM and DAM platform streamlines product data management.

Share This Article:

In this Article

Why Product Data?

All businesses exist because they sell a product or service. The problem is that there is always more than one company vying for customer attention. That is why businesses, no matter the designation, work tirelessly to develop strategies to sell as many products as possible.

Driving sales is often the ultimate goal of the strategies. According to an analysis by Jebbit, focusing on increasing sales is vital to your business as it directly impacts revenue generation, fuels business growth, provides financial stability, drives customer acquisition and retention, helps you gain market share, and contributes to product improvement.

Typically, businesses design and implement marketing campaigns to create awareness, generate leads, and nurture prospects. Conversely, sales teams utilize marketing collateral and messaging to close deals. Common among these functions is product data.

Marketers use product data to design campaigns that highlight product features and benefits, generating leads. The sales team then uses product data to address final queries and close the sale. Even post-sale, product data is used for customer support and feedback. Thus, accurate product data is key to marketing, sales, and customer satisfaction.

Therefore, it comes as a surprise that most companies do not identify as data-driven, especially concerning product data. A Harvard Business Review (HBR) analysis found that companies identifying themselves as data-driven have declined in each of the past few years despite increasing investment in big data and AI initiatives.

Could the decline be due to businesses underestimating the value of data, especially product data? Such a scenario often leads to businesses struggling to use product data effectively. If you find yourself in such a scenario, this article is invaluable because it shows the tools to help you use product data effectively to drive sales.

Understanding Product Data in the Industrial Sector

What is product data?

Product data is the collection of relevant and accurate information about a product. The information helps businesses and customers understand what the product does, enabling them to make informed decisions.

In the industrial sector, product data refers to products’ technical and functional attributes. These attributes provide crucial details that support the product’s design, production, delivery, and maintenance. The most important aspect of these attributes is that they can be read, measured, and structured into a usable format.

The nature of industrial products means that the attributes vary significantly, and a single product might have thousands of them. This is the main reason why the information that describes a product is not the same throughout its lifecycle. For instance, the attributes that are relevant at the design and engineering stages may not be essential at the sales phase.

What is important to note is that in the industrial context, product data supersedes basic details like name, price, and size. Here’s a breakdown of what it typically includes based on the stage in the product lifecycle:

- Design stage:

- Technical specifications: These define the product’s intended performance and functionality.

- Engineering drawings and 3D models: These visually represent the product’s structure and functionality.

- Engineering stage:

- Bill of Materials (BOM): This lists all the components, parts, and sub-assemblies required to manufacture the product.

- Manufacturing stage:

- Safety Data Sheets (SDS): These provide information about the safe handling, storage, and disposal of any hazardous materials used in the product.

- Sales stage:

- Marketing materials: These are used to promote the product and attract potential customers.

- Product pricing: This helps determine the product’s market positioning and profitability.

- After-sales support stage:

- Maintenance and repair instructions: These help users maintain and troubleshoot the product effectively.

- Compliance documentation: This ensures the product adheres to relevant industry regulations and safety standards.

- Customer feedback: This can provide insights for product improvement and innovation.

- Warranty information: This outlines the terms and conditions of the product warranty.

How do customers use this product data?

Most industrial products have a particular set of buyers. These are customers who probably represent an organization and buy your product to fix a specific problem in their operations. Therefore, unlike individual consumers, industrial buyers never make impulsive purchasing decisions.

Buyers must make informed and efficient purchasing decisions based on accurate and current product data. This is because industrial buyers (often categorized under the B2B label) are often responsible for sourcing large quantities of materials, components, or equipment that are critical for their manufacturing processes, operations, or projects. Therefore, they have to consider various factors such as quality, performance, functionality, compatibility, reliability, cost, availability, and delivery time.

Here is how they typically use product data to jump through the many hoops of the B2B buying process.

Stage one: Research

The process begins with research. Buyers use product data to understand the target product’s technical specifications, performance, and compliance certifications. They may also review engineering drawings and 3D models to understand the product’s structure and functionality clearly. This helps them identify products that might meet their needs.

Stage two: Comparison

Once they have a shortlist of potential products, buyers compare them based on factors like price, quality, performance, and compliance with industry standards. They may use tools like comparison charts or matrices, which are often based on product data.

Stage three: Evaluation

Buyers then evaluate the shortlisted products in more detail. They might review safety data sheets, especially if the product involves hazardous materials. They may also consider factors like the product’s maintenance requirements and the availability of after-sales support.

Stage four: Purchase decision

Based on their research, comparison, and evaluation, buyers make their final purchase decision. Accurate and comprehensive product data can give them the confidence to choose a product that best meets their needs.

Stage five: Post-purchase evaluation

Even after the purchase, buyers continue to use product data. For example, they might refer to maintenance and repair instructions to ensure the product is kept in good condition. They might also review warranty information and compliance documentation.

Throughout this multi-stage process, industrial buyers heavily rely on product data to understand product capabilities, ensure compliance with industry regulations, and make cost-effective purchasing decisions. As such, brands that fail to provide accurate and easily accessible product data risk losing out on sales opportunities to competitors with better data management practices.

The Challenges of Product Data Management for Industrial Brands

We said earlier that fewer-than-expected companies identify themselves as data-driven. This happens when all kinds of data have become invaluable to business operations. We speculated that perhaps the driver of this trend is businesses underestimating the value of data. But what if the real culprit is that companies are unable to overcome the challenges of data management?

Industrial brands must not only provide accurate and up-to-date product information but also ensure they are accessible across as many touchpoints as possible. This introduces the challenge of consistency—customers prefer a seamless experience across touchpoints.

Therefore, brands must find a way to overcome the challenges. But they must know and understand them first. Here are some challenges you’re likely to encounter:

1. Complex product specifications

Industrial products are often highly technical. This means they often have complex specifications, features, and usage requirements. These products are typically designed for specific, often specialized, applications and require a certain level of expertise to use effectively.

Let’s illustrate this with power tools. Power tools often come with detailed technical specifications such as power output, speed (RPM), torque, voltage, and amperage. For example, a cordless drill might have a specification like “20V MAX* 1/2 in. Cordless Drill/Driver Kit with a high-performance motor that delivers 300-unit watts out (UWO) of power.”

The tools also have specialized features designed for specific tasks. For example, a circular saw might have an adjustable bevel capacity for angled cuts, or a power drill might have a hammer function for drilling into concrete.

Regarding user requirements, the tools may require specific safety equipment and procedures to operate safely. For example, users might need to wear safety glasses, gloves, and hearing protection when operating a power tool. They might also need to follow specific procedures to avoid injury, such as securing the workpiece with clamps and keeping their hands away from the cutting area.

In short, a single product has many attributes. Multiply this across hundreds of product variants and models, and the volume of technical data becomes overwhelming.

Moreover, industrial product specifications are often deeply nested in hierarchies, with top-level products containing numerous sub-assemblies and individual components—each with its own set of attributes. Maintaining relationships and inheritance rules across this complex data structure presents a significant challenge.

The business suffers severe consequences if the complex product specifications are poorly managed, including:

- Costly mistakes in manufacturing, procurement, and sales.

- Inefficient processes, leading to delays, missed deadlines, and increased costs.

- Lost sales opportunities and reduced revenue.

2. Diverse customer needs

The customer base for industrial products is highly diverse. Buyers span different industries, company sizes, and geographic regions. This diversity translates into a wide range of specific requirements and use cases that the product data must address.

For instance, a manufacturer of industrial sensors may sell the same product line to automotive companies, oil and gas firms, and food processing plants. However, each of these customer segments likely has distinct priorities and criteria they use to evaluate the sensors.

Automotive companies may prioritize sensor accuracy and durability for harsh environments, while food processors may be more concerned with sanitary design and compliance with food safety regulations. On the other hand, oil and gas customers may heavily weigh hazardous area certifications and temperature/pressure ratings.

Capturing and organizing this nuanced product data to serve different customer needs is a significant challenge. Simply having a broad set of specifications is insufficient – the data must be tailored, contextual, and easily discoverable based on each customer’s unique requirements.

Furthermore, customers often use different terminology and jargon specific to their industries. An effective product data strategy must account for these vocabulary differences to ensure customers can find and understand the information they need during product evaluation.

Failing to address the needs of a diverse customer base has several severe consequences, including:

- Customer dissatisfaction: If customers cannot find the product information relevant to their specific needs, they may become frustrated and choose a competitor.

- Increased support costs: If customers cannot find the information they need, they are more likely to contact customer support, increasing the company's workload and costs.

- Wasted resources: Creating generic data sets that don't address specific needs can be inefficient and waste resources.

3. Regulatory compliance

Besides their complex nature, industrial products can endanger safety when mishandled. That is why manufacturers are obligated to ensure a safe environment when their products are in use. This explains the many and wide-ranging regulations and compliance standards subjected to industrial products. So, industrial brands must ensure that product data reflects the requirements.

Depending on the product category, there may be mandatory regulations around product safety, environmental impact, import/export, hazardous materials, and more. For example, industrial chemicals must comply with REACH regulations in the EU, while electrical equipment sold in North America requires certifications like UL or CSA.

Beyond mandatory regulations, there are also voluntary standards and certifications that industrial buyers often require, such as ISO, ANSI, ATEX, and industry-specific credentials. Manufacturers must capture this compliance data for their products.

The challenge is that regulations and standards constantly evolve across different jurisdictions. So, industrial brands must have processes and tools to monitor changes and update product data accordingly.

Moreover, complex supply chains and product variants exacerbate this challenge. A single component sourced from a different supplier could alter the product’s compliance status. Managing this matrix of regulatory data across multi-level product hierarchies is a demanding task.

There is no way around the regulatory requirements, and the consequences of non-compliance can be punitive. For instance:

- Regulatory bodies can impose hefty fines on non-compliant companies.

- If a product is found to be non-compliant after it has been released to the market, it may need to be recalled, leading to significant financial losses and reputational damage.

- Non-compliant products may be barred from entering certain markets, limiting the brand's reach and potential revenue.

4. Data quality

You must ensure that your product data captures the most recent and accurate specifications, meets diverse needs, and complies with relevant regulatory requirements. But that is not the end of it. This data must also be credible and complete, that is, of the highest quality.

However, the sheer volume and complexity of product data that industrial companies deal with complicate the quest for quality. As discussed earlier, technical specifications, material compositions, regulatory certifications, and other product attributes can number in the hundreds or even thousands of data points.

Without specialized tools, ensuring the accuracy and consistency of this data across multiple systems and sales channels is error-prone and onerous. Even small discrepancies, like a mistyped product dimension or an outdated compatibility note, can lead to significant issues downstream.

Another factor impacting data quality is the involvement of multiple stakeholders in the product data lifecycle. For instance, product managers, engineers, quality teams, marketers, and sales teams all interact with and potentially modify product data. Without proper governance practices and defined processes, the functions can result in data silos, conflicting information, and version control issues.

Furthermore, product data is often sourced from external parties like suppliers and regulatory bodies. Ensuring the quality and timeliness of this third-party data integration is an additional challenge that industrial brands must address.

Poor product data quality can extract a huge price that may collapse the business. Some consequences include:

- Misinformed decisions: Inaccurate or incomplete data can lead to poor decision-making at various levels, from product development to sales and marketing.

- Customer dissatisfaction: Inaccurate product data can mislead customers, leading to frustration and a negative brand perception.

- Operational inefficiencies: Poor data quality can hinder operational processes, such as inventory management, order fulfillment, and customer service.

- Wasted time and resources: Sales teams and customer service representatives waste time resolving issues arising from inaccurate data.

5. Data security

Product data is a valuable asset—this is apparent from the discussion so far. However, this makes it a prime target for cyberattacks. Besides cyberattacks, internal threats, such as unintentional or malicious actions by employees, can also compromise data integrity and security. For instance, experienced team members may accidentally alter critical product details, or an intern could inadvertently delete the master file.

Brands must work hard to protect the data from unauthorized access, theft, and misuse, but it is not easy work. They must institute robust data security measures, including access controls, encryption, and regular security audits.

Moreover, brands must also ensure data privacy and comply with data protection regulations, such as GDPR. Balancing data accessibility for authorized users with stringent security measures is a challenging task that requires careful planning and implementation.

Each of the challenges addressed has a direct impact on sales. The challenges also make it evident that effective product data management is critical yet problematic for industrial brands.

Attempting to manage such product data using spreadsheets and basic digital tools is inefficient and risky. To truly capitalize on their product data and drive sales, industrial brands need robust, purpose-built solutions, such as PIM and DAM software.

How PIM and DAM Empower Industrial Brands to Manage Product Data Better and Drive Sales

What is PIM software?

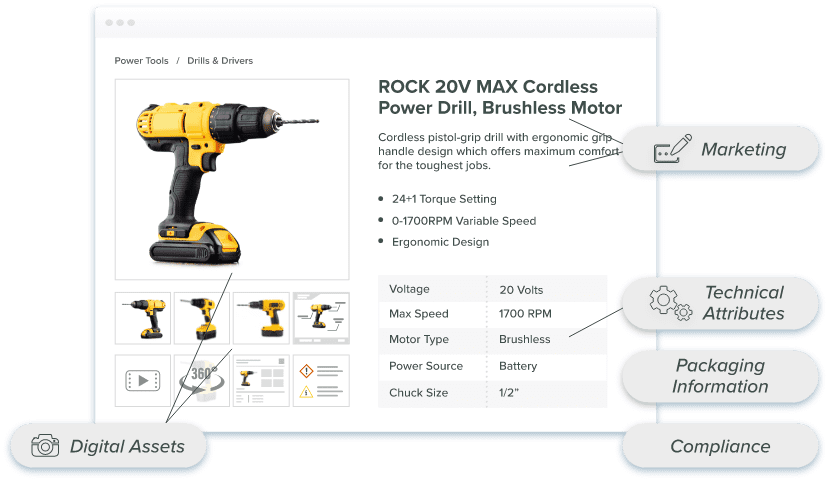

Product Information Management (PIM) software aggregates product data from several inventory management systems, such as spreadsheets, into a single source of truth. In other words, it is a command center for all your teams to operate from regarding product data.

PIM software provides several robust capabilities, such as the ability to create and manage product catalogs, categories, attributes, and variants, as well as complex product hierarchies and relationships.

In addition to introducing coherence to product details scattered across several inventory management systems, the tool allows you to add more information to the skeleton to create more compelling product data. This enrichment capability allows a PIM to make product information customer-facing. This means it provides sufficient details for customers to pick your items when evaluating options.

Moreover, a PIM allows users to automate critical workflows and processes, including data validation, approval, and publishing. The platform also integrates with other systems, such as ERP, CRM, or e-commerce platforms, enabling a seamless data transfer.

What is DAM software?

Like PIM software, a DAM solution stores, manages, and distributes product data. However, they differ in the data they handle. The former, as explained, handles textual data, and the latter deals with digital assets. This explains the name digital asset management, or DAM, in short.

Some of the files you’ll find in the DAM’s repository include product images, videos, manuals, compliance certificates, etc. These files and documents are essential for creating engaging and informative product experiences for customers. DAM software allows users to easily access, enrich, share, and distribute digital assets across different channels and platforms.

An industrial brand that sells machinery parts can provide an example of how DAM and PIM software differ. The brand needs to provide its customers with both textual and visual information about its products. The textual information, such as the dimensions, weight, material, and features of the parts, can be stored and managed by PIM software. The visual information, such as photos, videos, diagrams, and instructions for the parts, can be stored and managed by DAM software.

Why a unified PIM and DAM is the best configuration for product data management

Typically, brands acquire a PIM and DAM separately because most vendors offer them that way. This means they must connect them first before they can use them. The connection is necessary to map product details with corresponding digital assets. This process can be counterintuitive, especially for users who require seamlessness and zero points of failure.

Fortunately, some vendors, such as Catsy, offer a unified PIM and DAM solution, where the two systems are tightly integrated. This provides the ideal configuration for industrial brands to streamline product data management.

A unified PIM and DAM solution allows users to work within the same platform regardless of the data they are working on. This eliminates unnecessary clicks and navigation, enhancing productivity. This interconnected approach prevents inconsistencies and duplications that can occur when product data and assets are managed separately.

We learned that industrial products often have extensive details. The same applies to rich media—brands typically deal with 3D models, demonstration videos, and other critical media for sales and marketing. With PIM and DAM tightly integrated, it’s easy for users to map the right asset to descriptions, saving time and enhancing accuracy.

From an administrative standpoint, a unified PIM and DAM platform simplifies data governance by providing a “single pane of glass” to manage access controls, approval workflows, version histories, and audit trails for all product information assets.

How a unified PIM and DAM platform empowers industrial brands to manage product data better

Improved data quality, building customer trust and brand loyalty

The core strength of PIM and DAM systems is enabling industrial brands to maintain high data quality standards. With centralized products and assets in a single platform, companies can implement rigorous data validation rules and workflow approvals and automate data enrichment tasks. This ensures technical specifications, product descriptions, media assets, and other data remain accurate and consistent across sales channels. Delivering reliable product data builds customer trust and fosters brand loyalty in the B2B space.

Improved SEO for product listings

The core strength of PIM and DAM systems is enabling industrial brands to maintain high data quality standards. With centralized products and assets in a single platform, companies can implement rigorous data validation rules and workflow approvals and automate data enrichment tasks. This ensures technical specifications, product descriptions, media assets, and other data remain accurate and consistent across sales channels. Delivering reliable product data builds customer trust and fosters brand loyalty in the B2B space.

Enabling omnichannel commerce

B2B buyers and sales reps increasingly expect unified, media-rich product experiences consistently deployed across digital and physical touchpoints. Tightly integrated PIM and DAM solutions empower industrial companies to create an omnichannel-ready product catalog, syndicating complete product data with digital assets to e-commerce sites, print catalogs, retailers, and distributors.

Better inventory management and order fulfillment

A unified PIM and DAM platform connects product marketing content with operational data like inventory levels, pricing, and logistics details. This comprehensive view of the entire product lifecycle promotes better inventory forecasting, dynamic pricing adjustments, and streamlined order processing – resulting in greater operational efficiencies.

Final Thoughts

Product data is the foundation on which industrial brands can build a successful sales strategy. It has to be of the highest quality, meaning it must be complete and up-to-date, to meet the expectations of customers and partners across multiple channels and markets. PIM and DAM are handy tools to manage, enrich, and distribute product data efficiently and effectively, but they work best when tightly integrated into a unified platform. Such a platform offers seamless workflows, data consistency, and cross-functional collaboration. Brands that adopt a unified PIM and DAM solution can leverage their product data as a strategic asset and gain a competitive edge in the digital economy.

FAQs

High-quality, centralized product data in tightly integrated PIM and DAM allows industrial brands to provide customers with complete, trustworthy information to evaluate products against their requirements. This builds confidence, facilitates better decision-making, and prevents deals from stalling due to missing details – ultimately increasing sales conversions.

With a unified PIM and DAM solution, sales reps get direct access to up-to-date product specs, pricing, digital assets and support documentation in one place. They can quickly find information, build compelling sales presentations, and address customer queries promptly. This streamlined sales enablement process accelerates deal cycles.

Yes. This platform enables industrial brands to optimize e-commerce product data with rich descriptions, attributes, tags and media assets that boost on-site search and SEO rankings. The structured data can also be syndicated to distributors, marketplaces and industry catalogs to expand reach.

The integrated workflows in a unified PIM and DAM solution allow industrial brands to quickly collect, enrich and publish new product data with supporting digital assets to all sales channels. This gets new products to market faster with compelling content, enabling companies to quickly capture sales opportunities.

The primary metrics to track are:

- Revenue growth from products with enriched data vs. those without

- Increases in lead volumes from improved site search/SEO

- Faster sales cycles and higher lead conversion rates

- Increases in product page engagement (views, downloads, etc.)

- Lower abandoned cart/quote rates

- Reduced order errors and product returns

Establish benchmarks before implementing your product data strategy, then consistently measure these metrics over time. Combine with customer satisfaction surveys around product data. Focus on quantifying revenue impact, lead generation improvements, customer behavior indicators, and operational efficiencies gained from better product data utilization.